News Story

Fisher Lab Researchers Examine Novel Method for 3-D Printing of Biodegradable Vascular Grafts

Congenital heart disease (CHD) is the most common type of birth defect, affecting nearly 1 percent – about 40,000 – births per year in the United States, according to the Centers for Disease Control and Prevention.

While medical breakthroughs have helped babies with CHD live longer, healthier lives, Fischell Department of Bioengineering (BioE) researchers are working to address many of the most difficult complications associated with treating CHD.

For years, bioengineers have grappled with the fact that specific heart defects present unique problems in different patients due to anatomical differences. Proper design and adaption of implanted grafts to correct these defects is critical because graft orientation and shape directly are key to successful CHD surgical outcomes. Current grafts used in these procedures often suffer from progressive obstruction, infection, a lack of growth potential, poor long-term durability and other complications. In fact, 10-15 years after graft implantation, graft failure rates occur in as many as 70-100 percent of cases.

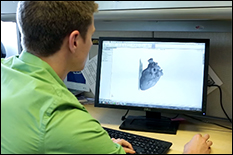

Fortunately, 3-D printing technology offers promise for today’s bioengineers looking to tackle these challenges head-on through the development of patient-specific vascular grafts using biodegradable materials.

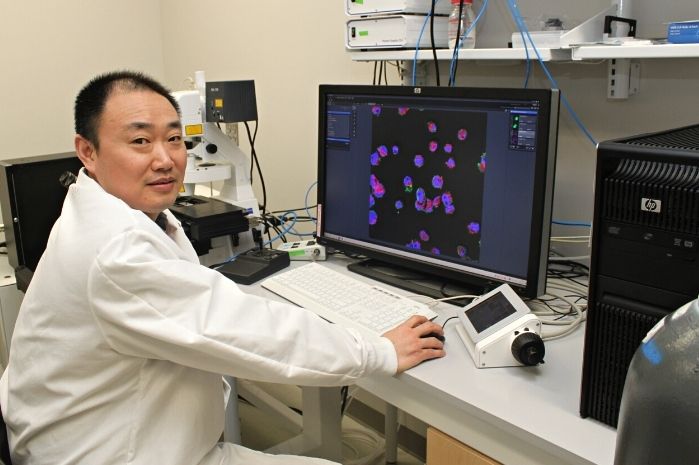

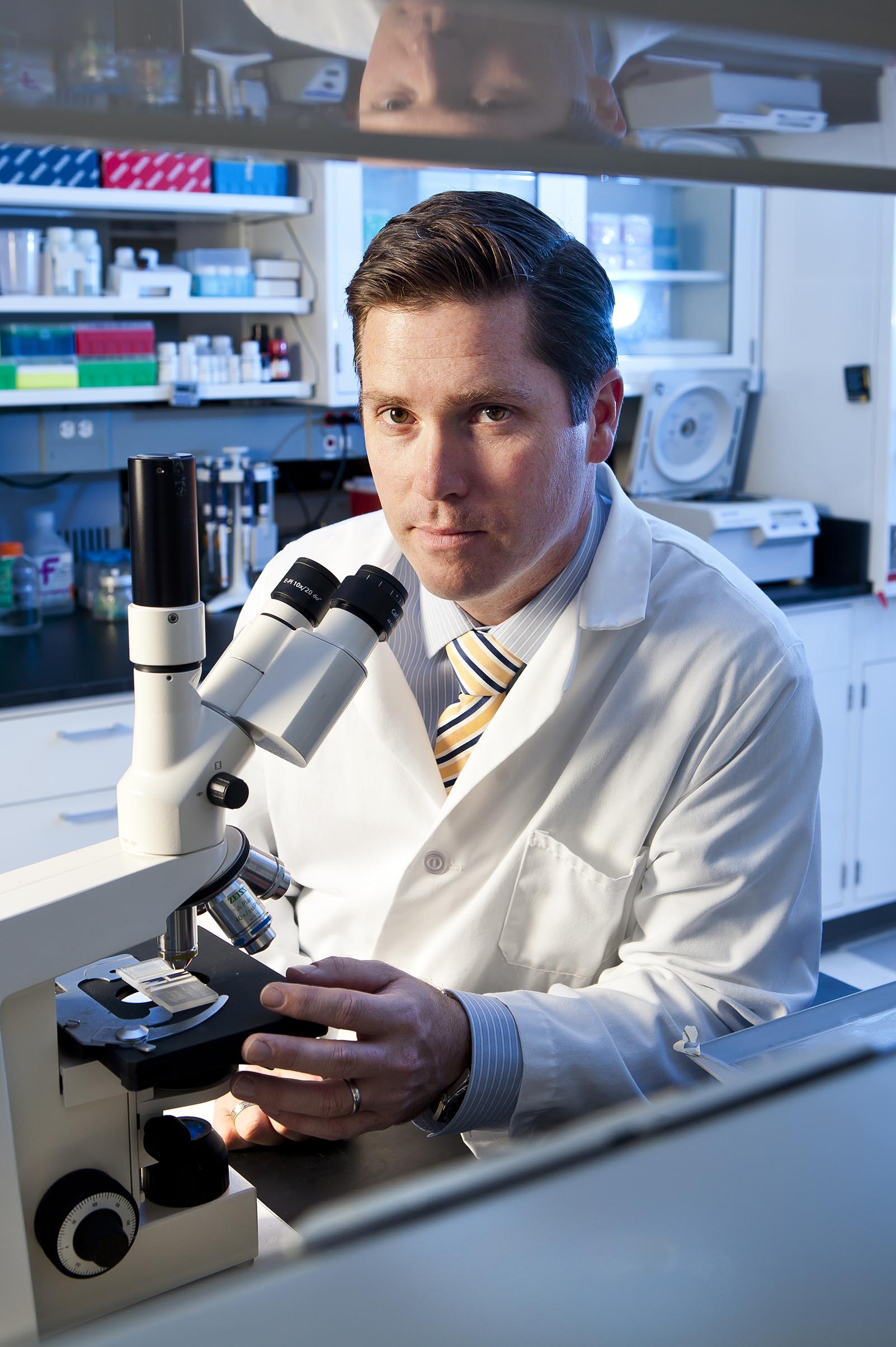

As experts in this arena, BioE Robert E. Fischell Professor and Chair John Fisher and members of his Tissue Engineering and Biomaterials Laboratory are developing a platform for the fully 3-D-printed fabrication of non-cellular biodegradable scaffolds for vascular tissue engineering. Their efforts, published this month in Advanced Healthcare Materials, include the examination of techniques and materials developed for the 3-D printing of vascular tissue-engineered scaffolds using poly(propylene fumarate) (PPF).

Nearly as soon as they first saw the technology come to life, bioengineers around the world recognized the tremendous potential for 3-D printing to change the way many of today’s most pressing medical challenges are treated. In the realm of tissue engineering, however, there are still many limitations to overcome.

Specific to vascular graft development, current bioprinting efforts have enabled the fabrication of biologically functional blood vessels. But, such vessels are best suited for vascularization of larger tissues, such as organs, due to material and size constraints. Additionally, most of the current methodologies for bioprinting fail to produce tissue-based grafts with adequate mechanical strength immediately after fabrication.

That is where members of Fisher’s laboratory hope their recent findings will come into play.

PPF is a biocompatible and biodegradable polyester that contains a carbon-carbon double bond along its backbone, enabling crosslinking between the polymer chains. These characteristics make PPF an ideal candidate for 3-D fabrication techniques that can be used to construct functional, tissue engineered scaffolds.

By printing the graft directly, Fisher’s team can also reduce the steps necessary to construct a scaffold. Even more, the group’s PPF grafts have demonstrated initial mechanical properties comparable to those of native vessels generally used in grafting procedures and appropriate for use as venous scaffolds.

The group believes that the material and technique developed in their study provides a powerful platform that can be expanded upon for the development of customized vascular tissue-engineering scaffolds using 3-D printing technologies.

Anthony Melchiorri (Ph.D. ’15), Chelsea Kraynak (B.S. ’15), and bioengineering undergraduate Lucas Kimerer served as authors on the paper, along with researchers and clinicians from Nationwide Children’s Hospital and Children’s National Health System’s Sheikh Zayed Institute for Pediatric Surgical Innovation.

Full text of the Advanced Healthcare Materials article, “3D-Printed Biodegradable Polymeric Vascular Grafts,” is available online.

Published December 15, 2015